Features and characteristics:

Function:

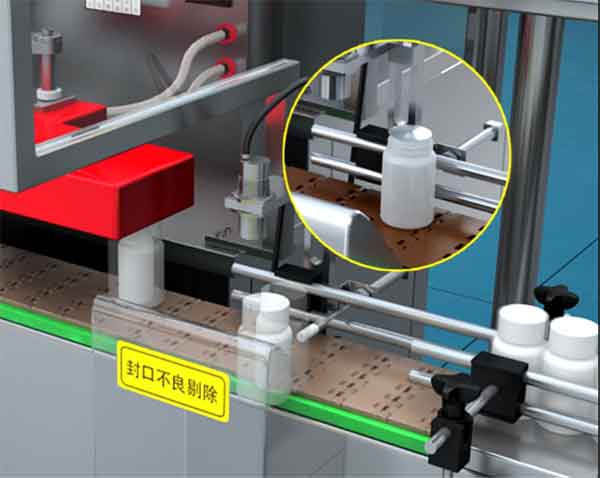

Online bottle leakage inspection after capping or aluminum sealing, unqualified bottle can be automatically rejected.

Parameter recipe can be stored and invoked

3-level authorization management meets the device operation management mechanism.

Machine has the function of electronic recording, electronic signature, audit trailing meeting FDA21 CFR PART11 requirements

Illustration:

Features:

Machine adopts negative pressure inspection without cap opened to inspect its sealing leakage, which will not cause a secondary pollution to the bottled medicine

Adopt international famous brand PLC and touch screen control system

With perfect anti-interference control system, it can resist the interference of electromagnetic interference (EMI), radio frequency interference (RFI), electromagnetic pulse (EMP) and other electronic systems

Machine can be matched with high speed bottle packing line

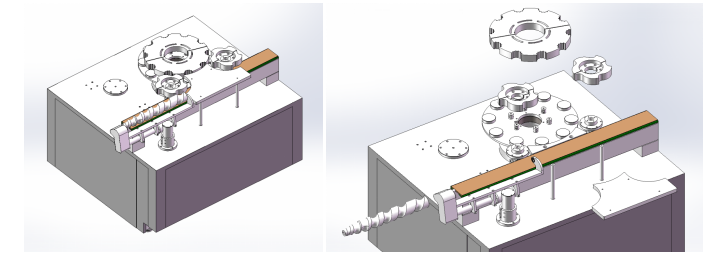

Illustration:

Quality risk control:

equipment can display real-time running time, product name, batch number, operator, equipment running parameters, can automatically count the output of qualified and unqualified products and a series of running data, data can be stored, uploaded, or external printer printing.

rejection mechanism has a real-time monitoring and confirmation system to ensure the unqualified products are accurately rejected.

equipment operation process meet the requirements of GMP, FDA and other regulations

qualified and unqualified products quantity can be tracked in real time through the touch screen

Illustration:

Safety alarm device:

3-color alarm light has intelligent voice and visual warning function, which is helpful to optimize personnel allocation and improve work efficiency

Safety door interlocking shutdown alarm device to ensure the personal safety of operators

Machine has inspection device of material shortage, bottle shortage and blocking

Simple operation, faster to change mold

user-friendly man-machine interface is easy to understand

modularization and tool-free design, simple and quick to change specifications by changing the corresponding mold

Administration personal can invoke the stored recipes to quickly switch for different products

Easy maintenance and cleaning

Convenient to disassemble and clean the equipment, easy to install again by positioning design.

Enjoy the Internet convenience in internet age

Ethernet data interface and OPC mechanism can be optioned, convenient user to access SCADA/MES system

Internet access and backup database, etc

Remote network maintenance can be realized

Make the most use of the Internet

Partial customer list:

Illustration:

Technical parameters:

Type | Capacity (pcs/min) | Suitable to bottle size |

JXL 4000Ⅰ | 50-200 | 20-1000 (special section can be customized accordingly) |